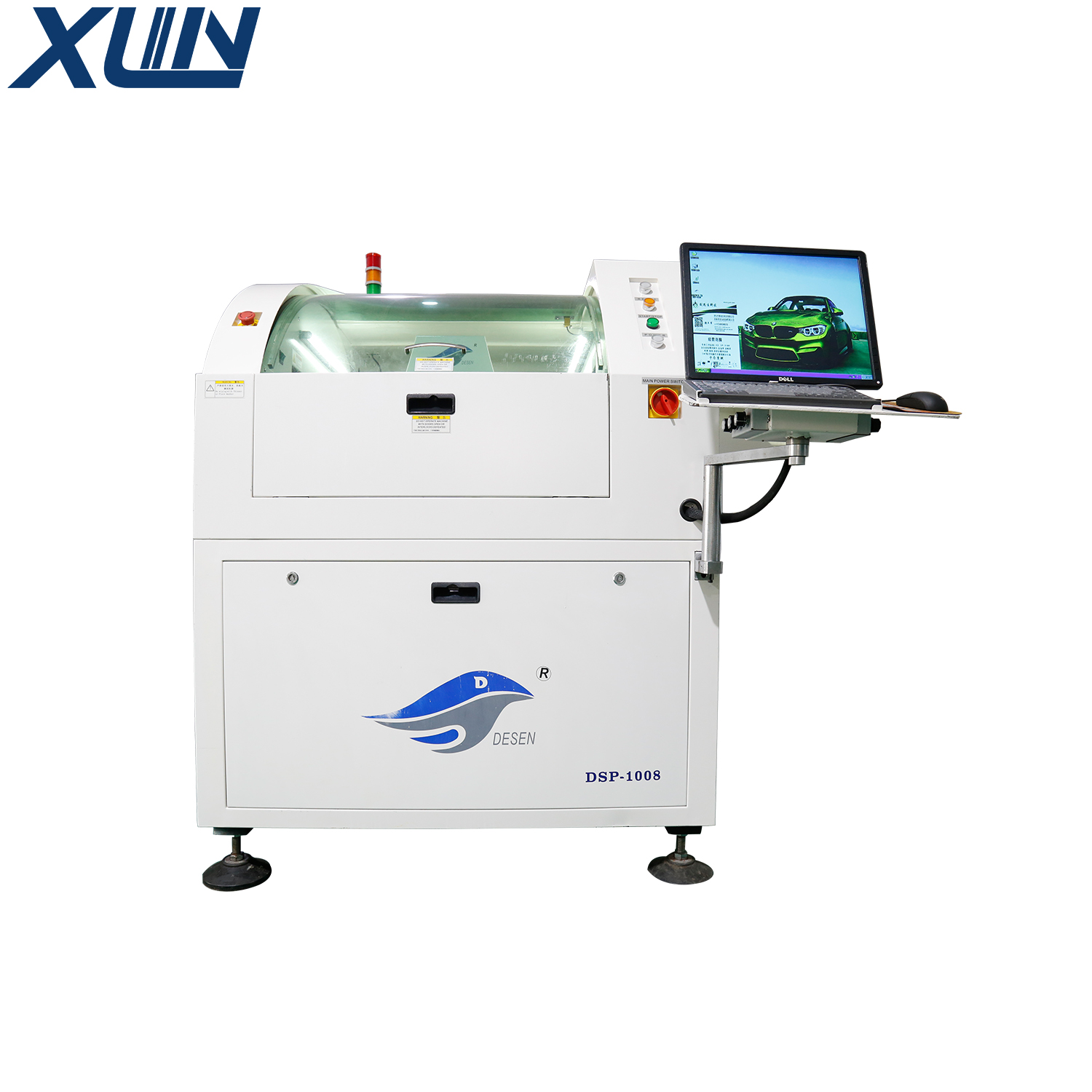

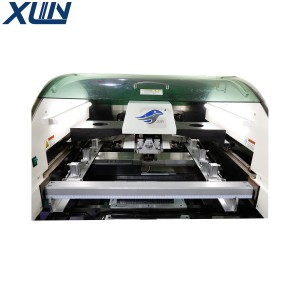

I-High Speed Full-Automatic PCB SMT Solder Paste Printer PCB SMT Stencil Printer

Umshini wokuphrinta wesimanje wokunamathisela we-solder ngokuvamile uhlanganiswa nokulayishwa kwepuleti, wengeza unamathisele we-solder, ukufakwa kwe-embossing, ukuhanjiswa kwebhodi lesifunda nokunye. Umgomo wayo wokusebenza uthi: qale ulungise ibhodi lesifunda elizophrintwa etafuleni lokumisa, bese kuthi ama-scrapers angakwesokunxele nangakwesokudla ephrinta avuze unamathisele we-solder noma i-glue ebomvu kuphedi elihambisanayo ngokusebenzisa insimbi yensimbi. I-PCB enokuphrinta okufaniswayo engekho ifakwa kumshini wokukhweza ngetafula lokudlulisa ukuze ifakwe ngokuzenzekelayo.

Izinyathelo zokusebenza zephrinta ezenzakalelayo ye-SMT:

1. Hlola futhi uqale okokusebenza ngaphambi kokusebenza ngokwezinqubo zokusebenza;

2. Beka i-PCB (i-PCB deformation ayikwazi ukuhlangabezana nezidingo zokukhiqiza, futhi ipuleti elisekelayo lizongezwa) kuhlaka lokulayisha;

3. Beka isikrini emshinini wokuphrinta ngokuya ngendlela ekhonjwe umcibisholo wesikrini;

4. Khetha uhlelo lokuphrinta oluhambisanayo ngokwemikhiqizo ekhiqiziwe, faka * * imodi yokulinganisa isikrini, futhi ulungise isimo sokuphrinta;

5. Ukulungiswa kokuphrinta: lungisa isivinini sokuphrinta, ingcindezi kanye ne-engeli ukuze wenze inani lokunamathisela kwe-solder liphrintwe kuyunifomu yephedi ye-PCB;

6. I-athikili yokuqala izoqinisekiswa uchwepheshe futhi ukukhiqizwa ngobuningi kuzokwenziwa ngemuva kokuthi ifaneleke;

7. Wonke amabhodi aphrintiwe angama-30 azohlolwa ngumhloli futhi athunyelwe kumshini wokukhweza ngemva kokuphumelela ukuhlolwa;

8. Ngemuva kokusebenza, susa ibhodi lesikrini bese ulihlanza, livale ngokwezinqubo zokusebenza, bese uhlanza ithebula lokusebenza.

Izidingo zephrinta ezenzakalelayo ye-SMT:

1. Gqoka amagilavu enjoloba noma amagilavu alahlwayo lapho usebenzisa i-solder paste. Uma i-solder paste inamathela ngengozi esikhumbeni, ngokushesha ihlanze ngotshwala kanye ne-sanitizer yesandla, bese uyihlanza ngamanzi amaningi;

2. I-solder paste esele, iphepha lokusula isikrini elisetshenzisiwe kanye namagilavu alahlwayo ngemva kokusebenza kuzophathwa ngokuhambisana nezinhlinzeko ezifanele zemithetho yezemvelo;

3. Hlanza amathuluzi, amathuluzi namathuluzi ngaphambi kokusetshenziswa, ikakhulukazi qaphela kakhulu isimo sokuvikelwa kwemvelo esizeni ngaphambi kokucubungula imikhiqizo engenamthofu.

Amapharamitha we-PCB

Imodeli ye-DSP-1008

Ubukhulu bosayizi webhodi(X x Y) 400mm×340mm

Ubuncane bosayizi webhodi 50mm×50mm

Ubukhulu be-PCB 0.4 - 5mm

Ikhasi le-Warpage ≤1%Diyagonal

Isisindo esiphezulu sebhodi 0-3kg

Igebe lemajini yebhodi lingu-20mm

Isivinini sokudlulisa 1500mm/s(Ubukhulu)

Dlulisa ubude ukusuka phansi 900±40mm

Dlulisa isiqondiso se-orbit Kwesobunxele-kwesokudla, Kwesokudla-Kwesobunxele, Kwesobunxele-Kwesobunxele, Kwesokudla-kwesokudla

Dlulisa Imodi yesiteji esisodwa

I-PCB damping indlela ehlelekayo ye-flexible side pressure + I-Adaptive PCB board ukujiya + I-Edge lock base clamp(Ongakukhetha: 1. I-vacuum eyingxenye yamaphoyinti amaningi ephansi; 2. Ukukhiya komphetho kanye nokubamba kwe-substrate)

Indlela yokusekela Ithiphu kazibuthe, ibhulokhi elinganayo ephezulu, njll.(Ongakukhetha:1.Igumbi leVacuum;2.Indawo yokusebenza ekhethekile)

Amapharamitha wokusebenza

Ukunemba kwempinda yokulinganisa isithombe ±10.0μm @6 σ,Cpk ≥ 2.0

Ukunemba kokuphinda kokuphrinta ±20.0μm @6 σ,Cpk ≥ 2.0

Isikhathi somjikelezo<7s(Ungafaki ukuphrinta nokuhlanza)

Ukushintsha komkhiqizo<5mins<br /> Amapharamitha wesithombe

Inkambu yokubuka 8mm x 6mm

Ibanga lokulungiswa kwenkundla X:±5.0mm,Y:±7.0mm,θ:±2.0°

Uhlobo lwephoyinti lokumaki Iphuzu lokuma elijwayelekile lomumo (i-SMEMA ejwayelekile), iphedi ye-solder/izivula

Uhlelo lwekhamera Ikhamera ezimele, isistimu yokubona phezulu/ephansi

Amapharamitha wokuphrinta

Ikhanda lokuphrinta Ikhanda lokuphrinta elintantayo elihlakaniphile (amamotho amabili azimele axhumeke ngqo)

Usayizi wozimele wesifanekiso 470mm x 370mm~737 mm x 737 mm

Indawo yokuphrinta enkulu(X x Y) 450mm x 350mm

Uhlobo lwe-Squeegee I-Steel scraper/Glue scraper (Ingelosi engu-45°/50°/60° ehambisana nenqubo yokuphrinta)

Ubude be-Squeegee 300mm(uyazikhethela ngobude buka-200mm-500mm)

Ubude be-Squeegee 65±1mm

Ugqinsi lwe-Squeegee 0.25mm Ukufakwa kwekhabhoni okufana nedayimane

Imodi yokuphrinta Ukuphrinta okukodwa noma okuphindwe kabili

Ubude be-demoulding 0.02 mm - 12 mm

Isivinini sokuphrinta 0 ~ 200 mm/s

Ingcindezi yokuphrinta 0.5kg - 10Kg

I-stroke yokuphrinta ±200 mm (Kusuka maphakathi)

Ukuhlanza Amapharamitha

Imodi yokuhlanza 1. Uhlelo lokuhlanza amaconsi; 2. Izindlela ezomile, ezimanzi kanye ne-vacuum

Ubude bokuhlanza nokusula ibhodi 380mm(ongakukhetha nge-300mm, 450mm, 500mm)

Izisetshenziswa

Izidingo zamandla 220±10%,60/60HZ-1¢

Izidingo zomoya ocindezelwe 4.5~6Kg/cm2

Ubukhulu bangaphandle 1114mm(L)*1360mm(W)* 1500mm(H)