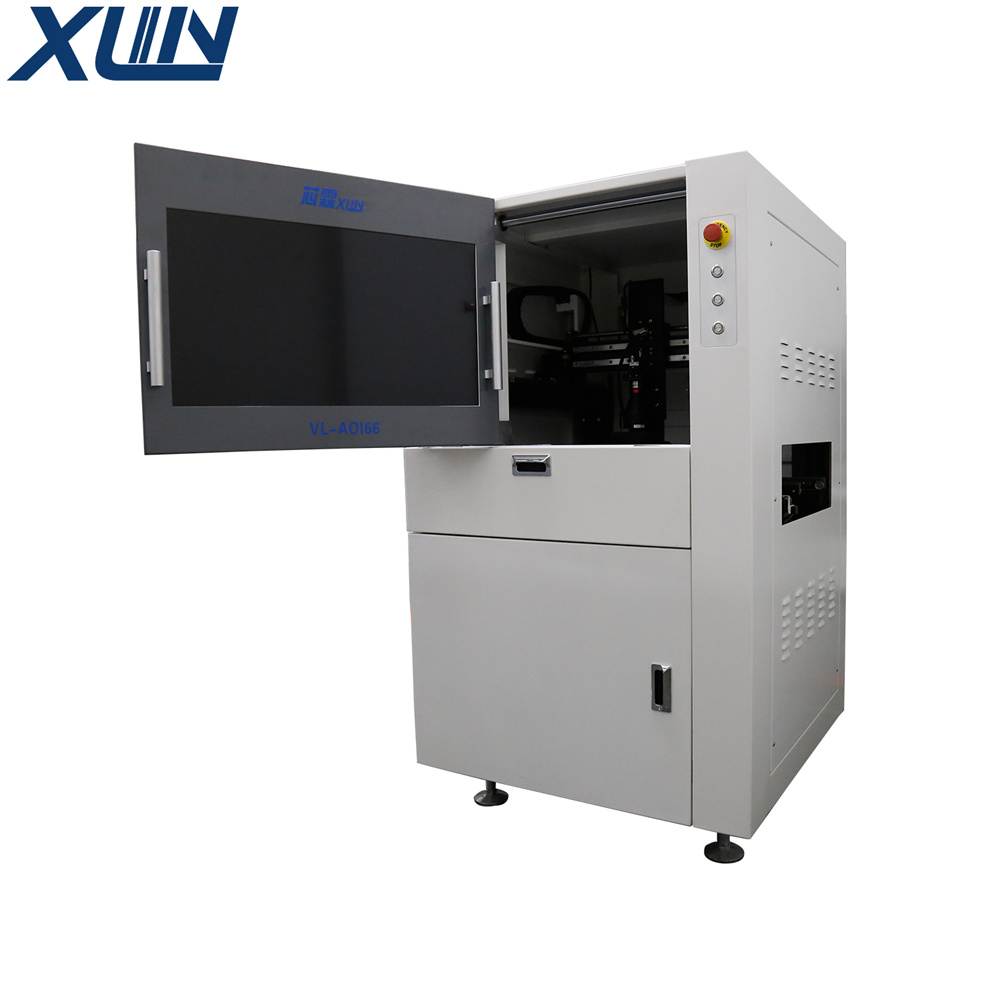

Ukunemba okuphezulu kwe-Xinling Single-Track Online AOI XLIN-VL-AOI66 yokuhlolwa kwe-PCBA

● Isixhumi esibonakalayo esilula nesinembile somshini womuntu, ngokuhambisana nemikhuba yansuku zonke elula nephumelelayo yokusebenza.

● Ukunemba okuphezulu, ikhamera yedijithali yombala wokucaca okuphezulu, umsebenzi ozinzile wokuthatha izithombe, ukubuyisela imiphumela yesithombe eyiqiniso nengokwemvelo, nokuzuza okukhipha isithombe sekhwalithi ephezulu. Ngombono, singakhetha amakhamera angenamkhawulo.

● Ilensi ye-Telecentric (ejwayelekile) Ukulungiswa okuphezulu, ukujula kwenkambu ebanzi kakhulu, ukuhlanekezela okuphansi kakhulu kanye nomklamo wokukhanya ohambisanayo ohlukile, njll., kungenza isithombe esicacile sokutsheka kwebhodi lesifunda kanye nezingxenye ezinde ngaphandle kokucweba amehlo.

● Isofthiwe ebanzi futhi eguquguqukayo, izidingo zokuqeqeshwa ezincane, kulula ukuyisebenzisa.

● Isilekeleli sokusebenza ukuze ugcine izilungiselelo zihambisana.

● Idizayini eshelelayo yomnyango yenza ukulungisa kube lula.

● Idizayini yobubanzi bokutholwa kosayizi omkhulu, engahlangabezana nezimfuneko zokutholwa kwama-PCB ahlukene.

● Ingasetshenziswa nesiteshi sokuxhuma ibhodi esithola kabili i-OK/NG ukuze ubone ngempela ukuxhumeka okungenamthungo kokuhlolwa kwe-inthanethi, ukwamukela ibhodi nokugcinwa, nokusekela uxhumano oluzenzakalelayo nemishini yangaphambili nangemuva kulayini wokukhiqiza (uhlobo lwe-inthanethi).

● Idizayini yohlelo olungaxhunyiwe ku-inthanethi kanye nokusetshenziswa komsebenzi wokulungisa iphutha ungaxhunyiwe ku-inthanethi ukuze kwandiswe ukusetshenziswa kwezinto zokusebenza.

● Ukusetshenziswa okuphelele kwama-algorithms asebenzayo ahlukahlukene, ukusetshenziswa kwesofthiwe kuyavumelana nezimo.

● Ukusebenzisa amatheminali eselula ngaphansi kwenethiwekhi engenazintambo kungase kumise iziteshi zokusebenza kunoma iyiphi indawo kushabhu, kusebenzisa imodi eyodwa kuya kweziningi, futhi kuqinisekise idatha yokutholwa kwemishini eminingi eku-inthanethi ngokusebenzisa indawo yokusebenza yokulungisa ukuze kufezwe injongo yokonga abasebenzi. Ingakwazi ukwazisa ngokunembile igama lesici, futhi isekelwa uhlelo oluphelele lwesizindalwazi se-SQL. Ihlinzeka ngohlelo lokuhlaziya izibalo lwe-SPC ngendlela yamashadi ophayi nama-histogram, olulungele amakhasimende ukwenza ukuhlaziya inqubo kanye nokwenza ngcono ikhwalithi.

● Ama-algorithms okuphendula akhethekile afana nokubonwa kwezinhlamvu ze-OCR nokuhlolwa kwendlela kungahlangabezana ngokuphumelelayo nokuhlolwa kwekhwalithi ngemva kokuphrinta, futhi izinga lokutholwa nezinga lokudlula liphezulu.

● Isistimu yokulawula ehlakaniphe kakhulu, ukuqapha ngesikhathi sangempela isimo sekhwalithi yomkhiqizo kanye nokusabela okufika ngesikhathi.

● Bona ukuxhunywa okuzenzakalelayo kwezindinganiso zengxenye nge-CAD, noma umshini wokubeka ukuze ungenise idatha yokuxhumanisa ukuze kutholakale ukuzenzakalelayo komklamo wohlelo.

Ibhodi lesifunda lihlolwe ngemva kokuphrinta kokunamathisela kwe-solder ye-SMT, ngaphambi/ngemuva kokudayiswa kabusha kwe-SMT, ngaphambi/ngemuva kokusoda kwegagasi kwe-DIP, ibhodi elithambile, i-aluminium substrate.

Indlela yokuthola ihlanganisa ama-algorithms angu-26 njengokufunda okujulile, ukuhlaziya i-vector, ukubala umbala, ukukhipha umbala, ukubala okumpunga, ukuqhathanisa isithombe, i-OCV/OCR, njll., futhi kuzoqhubeka nokukhula (ukufanisa isifanekiso, ukutholwa okuhlakaniphile, ukwahlulela okuhlakaniphile, ukubonwa kwebhakhodi) , ukubonwa kwekhodi ye-QR, ukubonwa kohlamvu, ukuqinisekiswa kohlamvu, ukubonwa kwevelu yokumelana, ukutholwa kombuthano, ukutholwa kwe-polarity, ukutholwa kokuklwebheka, ukutholwa kwebhuloho, inani elimaphakathi, inani eliphezulu, inani eliphansi, inani lobubanzi, inani elimaphakathi lendawo , Ukukhishwa kokukhanya, ukuhlukana okuhlobene, 2 -ukutholwa kwe-engeli yokuphela, ukutholwa kwe-collinearity, ukukhiqizwa kwengxenye engaphansi, inani elibaliwe, ukutholwa kwebhodi lonke [+], ukutholwa kwebhodi lonke [-], ukuma ngakunye)

Ikhamera yokulungiswa kwekhamera/ilensi: amaphikseli ayizigidi ezi-5-20, ikhamera yedijithali enombala ogcwele enesivinini esiphezulu. Silawula ukuthuthukiswa kwekhodi yomthombo futhi ngokombono sinokukhetha okungenamkhawulo kwamakhamera. Ukulungiswa kwelensi: 7um/10um/15um/20um/25um, okungenziwa egcizelele izicelo ezikhethekile. Ilensi ejwayelekile ye-telecentric.

Umthombo wokukhanya Ngokuya ekucushweni kohlelo lokusebenza lomthombo wokukhanya weziteshi eziningi ezimise okwendandatho enezinhlangothi ezintathu, khetha ukucaciswa okufanayo kwe-RGB nomthombo wokukhanya we-coaxial.

Imodi yokuhlela Ukubhala ngesandla, ukusesha okuzenzakalelayo, ukungenisa idatha ye-CAD kanye nomtapo wezincwadi ohambisanayo ozenzakalelayo.

Ukuthola uhlobo lwekhava ye-Solder Namathisela ukuphrinta: ubukhona noma ukungabikho, i-offset, ithini elincane, ithini eningi, isifunda esivulekile, ithini eqhubekayo, ukungcola, imihuzuko, njll.

Izingxenye ezingalungile: izingxenye ezingekho, izingxenye eziningi, i-offset, i-skew, amatshe amathuna, ukuma eceleni, izingxenye ezigingqikile, izingxenye ezingalungile, ezilimele, ezihlehlisiwe, i-XYθ offset, njll.

Ukukhubazeka kokuhlangana kwe-solder: ithini eliningi, ithini elincane, ukusoda okungamanga, ithini eqhubekayo, amabhola kathayela, ukuchichima kweglue, ukungaphumi komthofu, ukungcoliswa kwefoyili yethusi, njll.

Imisebenzi Ekhethekile Shayela uhlelo ngokuzenzakalelayo, thuthukisa ukutholwa kwebhodi lonke, i-jigsaw kanye namamaki amaningi, uphawu olubi, ukuhlolwa okunezici eziningi ngasikhathi sinye.

Ingxenye encane yokuhlola i-chip 01005, i-0.3 pitch IC. Lungisa ukucushwa kwe-optical ngokusho kwenqubo yekhasimende.

I-SPC kanye nenqubo yokulawula idatha yokuhlolwa kwerekhodi kuyo yonke inqubo futhi yenze izibalo nokuhlaziya, buka isimo sokukhiqiza nokuhlaziywa kwekhwalithi, namafomethi ombiko ophumayo njenge-Excel, Txt, ne-Word.

Isistimu yebhakhodi Ukubonwa kwebhakhodi okuzenzakalelayo (ikhodi ye-1D noma engu-2D), ekwazi ukubona amabhakhodi amakhulu kakhulu (ukuhlanganisa okuhlakaniphile kwe-FOV okuningi).

Isistimu yokusebenza Windows 10 x64 isistimu yokusebenza, isiShayina noma inguqulo yezilimi eziningi, isistimu yokusebenza yakamuva.

Umphumela wokuhlola ophumayo ongu-32-intshi we-LCD ukubonisa, isignali ye-OK/NG.

PCB usayizi ububanzi Min: 50 * 50mm; Ubukhulu: 460 * 400mm; kungenziwa egcizelele izicelo ezikhethekile.

Ubukhulu be-PCB ububanzi busuka ku-0.3 kuye ku-5 mm

Igebe lonqenqema lohlelo lwe-PCB, alinamuntu phakathi kuka-3.5mm wonqenqema lwebhodi.

Isisindo esiphezulu se-PCB 3KG

Idigri yokugoba ye-PCB engu-<5mm noma u-3% wobude be-diagonal ye-PCB

I-PCB phezulu naphansi ecacile ukuphakama kwe-PCB phezulu (Uhlangothi Oluphezulu): 30mm PCB phansi (Uhlangothi Oluphansi): 80mm

Isistimu ye-Conveyor Ephansi-phezulu engaguquki, isinxephezelo esizenzakalelayo sokugoba kwe-PCB, ukungena nokuphuma okuzenzakalelayo ebhodini, ibhande eliyisicaba, ukulungiswa kobubanzi okuzenzakalelayo.

Imvume yomhlabathi ye-Conveyor 880 kuya ku-920 mm

Isiqondisindlela/isikhathi sokugeleza singasethwa siye kwesokunxele→kwesokudla→kwesokunxele ngokusebenzisa isofthiwe. Isikhathi sokungena/sokuphuma: 3-5 imizuzwana.

X/Y platform drive Screw kanye AC servo motor drive, PCB fixed, Ikhamera ihamba X/Y direction, iyunithi ngayinye isiphasile isitifiketi.

Ukunikezwa kwamandla AC220V 50/60Hz 1.5 KW

Umfutho womoya 0.4~0.8Mpa

Front nangemuva idivayisi ukuxhumana Smema

Equipment isisindo mayelana 650KG

Ubukhulu besisetshenziswa: L1000 (ubude bomzimba othathwayo) * W1000 (ngaphandle kwezinsiza zokubamba) * H1660 mm, ukuphakama akubandakanyi izibani zesignali.

Izinga lokushisa le-ambient nomswakama 5~35℃ 35~80% RH (akukho ukufingqa)

Imithethonqubo yokuphepha kwezisetshenziswa Ihambisana namazinga okuphepha e-CE

Uhlelo lwesiteshi Lokulungisa Ongalukhetha, uhlelo lokuhlela olungaxhunyiwe ku-inthanethi, uhlelo lweseva ye-SPC, uhlelo lokuqaphela ibhakhodi, isikhombimsebenzisi se-MES / isikhombimsebenzisi se-Shop Floor.