Abantu abaningi bangase bangazi ukuthi usetshenziswa kanjani umshini wokubeka, bachaze isimiso somshini wokubeka, nokusebenza okuphephile. Imboni ye-XLIN ibambe iqhaza ngokujulile embonini yemishini yokubeka iminyaka engu-15. Namuhla, ngizokwabelana nawe ngesimiso sokusebenza kanye nenqubo yokusebenza ephephile yomshini wokubeka .

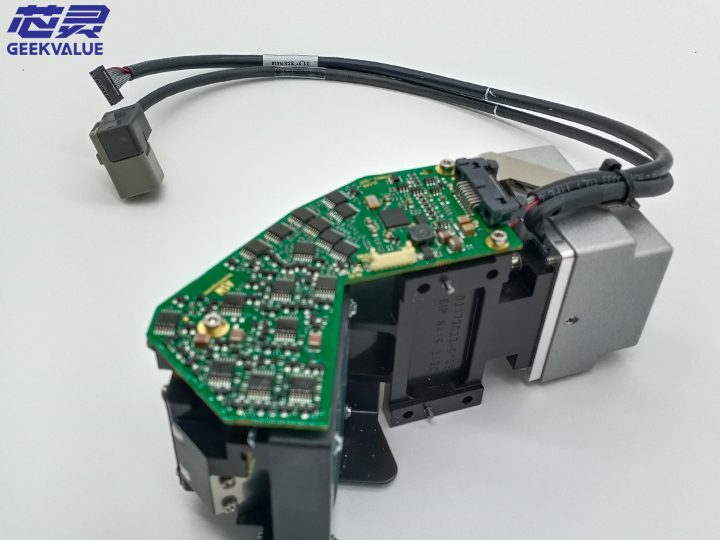

Umshini wokubeka: owaziwa nangokuthi "umshini wokukhweza" kanye "Nesistimu Yentaba Yokuphezulu", emgqeni wokukhiqiza, ulungiswa ngemva komshini okhiphayo noma umshini wokunyathelisa isikrini, futhi isistimu yokukhweza phezulu ifakwe ngokuhambisa ikhanda elikhuphukayo. Idivayisi ebeka ngokunembile izingxenye kumaphedi e-PCB. Umshini wokubeka uyinhlanganisela yomshini, ugesi, ukukhanya nobuchwepheshe bokulawula ikhompuyutha. Ngokumunca, ukususwa, ukubeka, ukubeka kanye neminye imisebenzi, izingxenye ze-SMC/SMD zinganamathiselwa ngokushesha nangokunembile endaweni eqokiwe yephedi ye-PCB ngaphandle kokulimaza izingxenye kanye nebhodi lesifunda eliphrintiwe.

Kunezindlela ezintathu zokubeka maphakathi nendawo zokukhweza izingxenye emshinini wokubeka: i-mechanical centering, i-laser centering kanye ne-visual centering. Umshini wokubeka uqukethe uhlaka, i-xy motion mechanism (isikulufu sebhola, igayidi yomugqa, imoto yokushayela), ikhanda lokubeka, isiphakeli sengxenye, indlela yokuphatha ye-PCB, idivayisi yokuhlonza ukuqondanisa kwedivayisi, kanye nesistimu yokulawula ikhompuyutha. Ukunyakaza kwawo wonke umshini kubonakala ngokuyinhloko ngomshini wokunyakaza we-xy, amandla adluliswa ngesikulufu sebhola, futhi ukunyakaza okuqondisayo kutholwa ngomzila wesitimela ohambayo. Leli fomu lokudlulisela aligcini nje ngokumelana nokunyakaza okuncane, isakhiwo esihlangene, kodwa futhi nokusebenza kahle kokudlulisa.

1. Kunezinhlobo ezimbili zemishini yokubeka: manual kanye ne-othomathikhi ngokugcwele.

2. Isimiso: Isiphakeli sengxenye yohlobo lwe-arch kanye ne-substrate (PCB) zilungisiwe, futhi ikhanda lokubeka (elifakwe namabhomu okumunca ama-vacuum amaningi) liya emuva naphambili phakathi kwesiphakeli kanye ne-substrate ukuze kukhishwe izingxenye kusiphakeli. Lungisa indawo kanye nesiqondiso, bese unamathela ku-substrate.

3. Ngoba i-patch head ifakwe ku-X/Y coordinate ugongolo olunyakazayo lohlobo lwe-arch, ngakho luqanjwe.

4. Indlela yokulungisa yendawo kanye nesiqondiso sezingxenye zesikhweli sohlobo lwe-arch: 1), lungisa indawo ngokubeka indawo ngomshini, futhi ulungise isiqondiso ngokuzungezisa umbhobho wokumunca. Ukunemba okungafinyelelwa yile ndlela kunqunyelwe, futhi amamodeli akamuva awasasetshenziswa.

5. Ukubonwa kwelaser, indawo yokulungiswa kwesistimu ye-X/Y, indlela yokulungisa ukuzungezisa umlomo wombhobho wokumunca, le ndlela ingakwazi ukubona ukuhlonza phakathi nendiza, kodwa ayikwazi ukusetshenziselwa ingxenye ye-BGA yokubonisa igridi yebhola.

6. Ukubonwa kwekhamera, indawo yokulungisa isistimu ye-X/Y, indlela yokulungisa ukuzungezisa umlomo wombhobho wokumunca, ngokuvamile ikhamera iyalungiswa, futhi ikhanda lokubeka lindiza linqamule ikhamera ukuze libonwe isithombe, okuthatha isikhathi eside kunokubonwa kwe-laser, kodwa iyakwazi ukubona. noma iyiphi ingxenye, futhi kukhona nokusetshenziswa Isistimu yokuqaphela ikhamera ukuze ibonwe phakathi nendiza inokunye ukuzidela ngokwesakhiwo sokusebenza.

7. Kuleli fomu, ngenxa yebanga elide lekhanda le-patch elihamba phambili naphambili, ijubane lilinganiselwe.

8. Ngokuvamile, imibhobho eminingi yokumunca i-vacuum isetshenziselwa ukucosha izinto ngesikhathi esisodwa (kufika eshumini) futhi isistimu ye-double-beam isetshenziselwa ukukhulisa isivinini, okungukuthi, ikhanda lokubeka phezu komugqa owodwa licosha izinto; kuyilapho ikhanda lokubeka kwelinye i-beam linamathela Ukubekwa kwengxenye cishe kushesha ngokuphindwe kabili njengohlelo lwe-single-beam.

9. Kodwa-ke, ekusetshenzisweni okungokoqobo, kunzima ukufeza isimo sokuthatha izinto ngesikhathi esisodwa, futhi izinhlobo ezahlukene zezingxenye zidinga ukushintshwa ngamabhomu ahlukene okudonsa i-vacuum, futhi kukhona ukubambezeleka kwesikhathi ekushintsheni imibhobho yokudonsa.

10. Isiphakeli sengxenye yohlobo lwe-turret sibekwe enqoleni yezinto ezihambayo ezididiyelwe eyodwa, i-substrate (PCB) ibekwe etafuleni lokusebenza elihamba ngesistimu yokuxhumanisa i-X/Y, futhi ikhanda lokubeka lifakwe ku-turret. Lapho isebenza, into esetshenziswayo Imoto igudluza ingxenye yokuphakelwa kwengxenye iyise lapho izothathwa khona, umlomo wombhobho wokufunza ekhanda lesichibi icosha izingxenye ezithile lapho kuthathwa khona, bese izungeza iye endaweni yokucosha phakathi kwe-turret (180). amadigri ukusuka endaweni yokulandwa). Lungisa indawo kanye nesiqondiso sezingxenye, futhi ubeke izingxenye ku-substrate.

11. Indlela yokulungisa yokuma kwengxenye nokuqondisa: ukuqashelwa kwekhamera, ukulungiswa kwesistimu ye-X/Y kudidiyelwe, isiqondiso sokuzishintshanisa se-nozzle yokumunca, ikhamera engaguquki, ikhanda lokubeka elindiza phezu kwekhamera ukuze kubonwe ukubonwa kwesithombe.

Ngaphezu kwalokho, umshini wokubeka umaka izingxenye ezibalulekile ezifana namashafti afakwayo, amalensi anyakazayo/amile, izibambi ze-nozzle kanye neziphakeli. Ukubona komshini kungabala ngokuzenzakalela izixhumanisi zalezi zinhlelo zesikhungo sokumaka, kusungule ubudlelwano bokuguqulwa phakathi kwesistimu yokuxhumanisa yomshini wokubeka kanye nesistimu yokuxhumanisa ye-PCB nezingxenye ezifakiwe, futhi ibale izixhumanisi ezinembile zomshini wokubeka. Inhloko yokubeka ibamba umlomo wokumunca, futhi incela izingxenye endaweni ehambisanayo ngokohlobo lwephakheji, inombolo yengxenye kanye neminye imingcele yezingxenye zokubeka ezingenisiwe; ilensi emile ithola, ibone futhi imise izingxenye zokumunca ngokuvumelana nohlelo lokucubungula okubukwayo; futhi idlule ekhanda elikhwezayo ngemva kokuqeda Faka izingxenye ku-PCB ezindaweni ezinqunywe kusengaphambili. Uchungechunge lwezenzo ezinjengokuhlonza ingxenye, ukuqondanisa, ukutholwa, kanye nokufakwa konke kuqedwa ngokuzenzakalelayo isistimu yokulawula ngemva kokuba ikhompuyutha yezimboni ithole idatha efanele ngokuya ngemiyalelo ehambisanayo.

Umshini wokubeka iyidivayisi esetshenziselwa ukubekwa kwezingxenye ngesivinini esikhulu nokunemba okuphezulu, futhi iyimishini ebucayi neyinkimbinkimbi kuwo wonke ukukhiqizwa kwe-SMT. I-Mounter iyimishini yokufaka ama-chip esetshenziswa ekukhiqizweni kwe-SMT. Umshini wokubeka ukubeka ngokunembile umshini wokubeka endaweni ehambisanayo, bese uwunamathisela ngeglue ebomvu eboshwe ngaphambili kanye nokunamathisela kwe-solder, bese ulungisa umshini wokubeka ku-PCB ngokusebenzisa kuhhavini ogelezayo.

Ukusebenza okuphephile komshini wokubeka kufanele kulandele imithetho nezinqubo zokuphepha ezilandelayo:

1. Amandla kufanele avaliwe lapho uhlola umshini, ushintsha izingxenye noma ulungisa kanye nokulungiswa kwangaphakathi (ukugcinwa komshini kufanele kwenziwe ngokucindezelwa inkinobho yezimo eziphuthumayo noma ukunqanyulwa kwamandla.

2. Lapho “ukufunda izixhumanisi” futhi ulungisa umshini, qiniseka ukuthi i-YPU (iyunithi yokuhlela) isesandleni sakho ukuze ukwazi ukumisa umshini nganoma yisiphi isikhathi.

3. Qinisekisa ukuthi okokusebenza kokuphepha “kwe-interlock” kuhlala kusebenza kahle ukuvala noma nini, futhi ukuhlolwa kokuphepha komshini ngeke kweqiwe noma kufinyezwe, ngaphandle kwalokho kulula ukubangela izingozi zomuntu siqu noma zokuphepha komshini.

4. Ngesikhathi sokukhiqiza, u-opharetha oyedwa kuphela ovunyelwe ukusebenzisa umshini owodwa.

5. Ngesikhathi sokusebenza, qiniseka ukuthi zonke izingxenye zomzimba, njengezandla nekhanda, azikho endaweni ehambayo yomshini.

6. Umshini kufanele umiswe kahle (usekelwe phansi ngempela, ungaxhunywanga ocingweni oluphakathi nendawo).

7. Ungawusebenzisi umshini endaweni enegesi noma engcole ngokwedlulele.

Isikhathi sokuthumela: Dec-17-2022